Lightning safety is an area that has eluded any significant interest by the usual industry heavyweights, where the granting of full Standard Patent for our LightningMat EPR Safety Mat, is something that I am particularly proud of, as we have demonstrated inventiveness where no prior art existed, where LightningMat has since been commercialized, and has so far been exported to four (4) continents, and more recently finding favor for use locally as PPE for use within Australian Gas and Power utilities.

So what to do NEXT!

My Lightningman work has exposed me to a wide variety of Lightning Management Plans (LMP), Safe Working Procedures (SWP), and Trigger Action Response Procedures (TARP) that various organizations have put in place to deal with their obligations to lightning safety, which inherently has a consequential negative impact upon operational productivity.

There is and has been a general lack of industry awareness towards any efficient balance of maintaining safety from lightning, versus maintaining optimum operational productivity, evidenced by a wide variance in the perception of lightning risks across high risk industry sectors, where one operation can take a particular workplace activity and assign it a particular TARP, which is then diametrically opposed to another operations perception of the same risk, and who assign a completely different TARP.

One of the more concerning aspects is how the mining sector deals with ‘load and haul’ activities associated with the operation of Heavy Mining Equipment (HME) operating across a ROM and Waste Dumps, where some site operations TARP will require HME operators to continue productive operations during Lightning Red Alert, whilst other organizations TARP will require HME operations to cease during Lightning Red Alert.

Additionally to this, some organizations TARP requires its operators park up their HME and remain in the vehicle until the all clear is notified, whilst another organizations TARP will require operators to park up their HME, and egress the vehicle, until the all clear is notified.

From a technical perspective the conditions required for a lightning stroke to strike HME will not differentiate between whether a HME is moving or stationary, and from a safety perspective, HME operators will still be exposed to the same level of risk irrespective of whether the HME is parked up or operating.

For such a significant and known hazard, this lack of commonality to the way that the industry sector handles lightning risks, and its understanding of the contributory risk factors, is astonishing.

So who is right, and who is wrong, and in any sophisticated HSEC environment, how can risk perception to a known fatal risk differ so greatly?

Lightning initiated pyrolysis involving HME, has been a widely publicized and hot topic for several years following numerous lightning initiated pyrolysis incidents involving HME that resulted in tyre explosions, where I have been seen as something of a lightning rod (excuse the pun) for the provision of industry awareness to the significant incident statistics, and providing information to the various states mining regulators, and to the mining sector in general

The most notable recent incident occurred in the Hunter Valley back in 2007, prompting DPI NSW to issue Safety Alert SA08-03-Lightning Strikes stationary truck. (see link below)

https://www.resourcesandgeoscience.nsw.gov.au/__data/assets/pdf_file/0017/204047/SA08-03-Lightning-strikes-stationary-truck.pdf

The Queensland DNRME have also published regular information on the subject

Whilst in WA the DMP/ DMIRS have published the following guidance.

But there have been many more lightning versus HME incidents, some of which had led to:

- significant damage to HME (including complete write-off of equipment)

- significant damage to surrounding mobile plant and buildings.

- significant lost productivity and operational disruptions

- several fatalities to HME operators (overseas operations)

Inflating tyres with Nitrogen has often been raised as being the solution to the tyre pyrolysis issue, although technical experts who I trust assure me that:

- pyrolysis is a chemical reaction that can persist in the absence of oxygen

- nitrogen filled tyres have been known to explode, as it is impossible to remove all oxygen from a tyre cavity, even with double inflation practices

- the storage of large quantities of nitrogen presents a whole new set of risks, that include asphyxiation in the event that leaks were to occur (Nitrogen is heavier than air)

- nitrogen stations are an expensive initial capital outlay, with high ongoing annual running, maintenance, and compliance costs

Anecdotal reports have also suggested that there have been instances where HME tyres had accidentally been filled with pure oxygen rather than nitrogen, due to human error.

So the use of Nitrogen will help, but it is not without its issues, nor is it the only solution worth investigating.

So having said all that, its probably the right time to introduce another Lightningman innovation into the mix, one that can manage the balance between providing lightning safety along with maintaining operational productivity.

Introducing,

Lightningman ‘LightningMast’ Safe Productivity Trailers.

Our LightningMast safe productivity trailers are a recent new innovation that offers higher risk operations an innovative and flexible means by which high value, high yield, and high risk HME operations can operate safely, and continuously without interruption during periods of Lightning Red Alert.

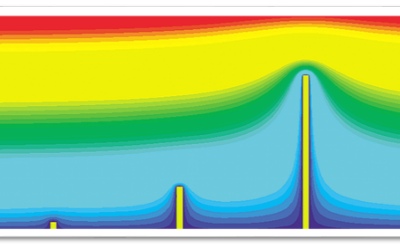

The LightningMast is a highly portable lightning protection system, that can be stationed strategically anywhere across high value/high yield production areas, and when deployed, establishes a “lightning protected working corridor” that allows high value production operations to continue during high risk periods.

The lightning protection concept follows the traditional ‘Rolling Sphere Design Methodology” as which is outlined within all reputable Australian and international lightning protection codes and standards, where our innovation has extended LPS capability through portability.

This Rolling Sphere protection methodology is as which is similarly applied across the mining industry for the protection of explosives magazines, and other high risk structures. and therefore ensures as far as practicable, the:

- optimum safety to operators,

- optimum protection to HME equipment

- optimum production across higher risk areas.

LightningMasts are heavy duty trailer mounted lightning protection systems that stow down to approx. 5.1 mtrs, which are then towed to the required location and then pneumatically deployed by an onboard compressor, solar panel, battery and recharge capability, that when extended presents a 22 mtr high Lightning Protection System.

Lightningmasts are engineered to withstand windspeeds of 40 kmh un-guyed, and 80 kmh when guyed to the Four (4) outriggers, and can be erected by a single person in less than 6 minutes.

The mobility of LightningMast trailers provide significant advantages over fixed lightning protection systems, where they can be stationed wherever, and whenever needed, although we do recommend that fixed Lightning Protection systems still have an important role to play, especially around trafficable areas, and then be used in conjunction with the LightningMast.

For example on a ROM, we would recommend that 2 x Freestanding Lightning Protection Systems be installed in a manner that bookends the crusher, where the LightningMasts can then be stationed every 80 mtrs along the working corridor which will provide an AS1768 Protection Level 4, that is stated as providing 85% statistical protection.

However greater distances between LightningMasts may also be possible whereby HME operating along the working corridor would then be regularly passing in and outside of reduced protection level for a few seconds and then entering back into an increased protection level, and so on, in which case there is an argument to be made that a reasonable level of protection would have been afforded across the working corridor.

For example in the Pilbara region of Western Australia, the Bureau of Meteorology show a ground flash density of between 2-4 cloud to ground strikes per km2 annum, in which case a HME passing in and out and in and out of reducing and increasing protection levels could offer a reasonable valid approach to an organization taking reasonable steps that would to mitigate the greater risk.

Im not sure of the odds where a lightning stroke would strike a HME at the exact time that it passed outside of the protected area for a few seconds when the likelihood is between 2- 4 cloud to ground strikes per year.

All activities involving dumping where a truck tray was lifted into the air, should always be conducted between two (2) Lightning Protection Systems (at the Crusher) and between two (2) Lightningmast Trailers (at the Tip Head) that are appropriately spaced.

A 789 Dump truck tray will be elevated some 13 mtrs into the air, on the edge of any already elevated landmass, and hence would have a higher probability for lightning attachment, unless of course there was an even higher point adjacent that had a higher E-Field intensification.

LightningMast can be easily applied to most high value production areas including:

- Elevated ROM areas – LightningMast can establish a protected working corridor (‘s) between the various grade stockpile(s) to the crusher, and cater to various grade feed requirements being loaded into the crusher.

- Elevated Waste Dump- LightningMast can establish a protected working corridor across the Waste Dump to the Tip head.

- Tip Points – The mobility of Lightningmast ensures HME can always tip between two (2) LightningMasts which can be easily relocated as and when the Tip Head moves.

- Elevated Heap Leach Dumping- LightningMast can establish a protected working corridor across the elevated heap leach area.

- TSF construction – LightningMast can establish a protected working corridor across the TSF to support dumping operations.

- HME Field Maintenance/ Breakdowns- LightningMast can be used to guard HME equipment during high risk periods

- Temporary Go Lines- LightningMast can establish a protected area around temporary Go line parkups

Lightningmast can be de-mobilized and mobilized as operations change, expand, contract, or can be re-deployed elsewhere at mine end of life.

Some Lightning 101

Elevated man-made landmass, and other man-made features over surrounding flat ground, will naturally converge the local electric field ( E-Field) during localized thunderstorms.

It is this convergence of the E-field around large and prominent structures/landmass that intensifies the electric field to the point that corona currents are developed, which can lead to semi thermalized streamer leaders being launched upwards on the close approach of a lightning down-leader.

This is the science of lightning, which is largely an invisible mechanism, and a microsecond event, where the fundamental basis in science as to how a lightning rod works is the efficient intensification of electric field at strategic points.

ROM, Waste Dumps, Heap leach, and TSFs are all considered as high risk areas due to their artificially elevated land mass over natural ground, where the landmass acts to converge the intensifying electric field during localized thunderstorms

Placing a 789 dump truck at the edge of a waste dump, which would already be exposed through a convergence of E- field, and then elevating the tray an additional 13 mtrs into the intensifying electric field, is just asking for trouble.

Any intensifying electric field will treat any large elevated landmass such as a ROM , Waste Dump, TSF, HME, Communications Tower, Processing plant, or an LPS, no differently than any large industrial or commercial construction where an architect/ engineer undertaking a risk assessment, would require lightning rods to be installed.

A thunderstorm isn’t intelligent that it can somehow differentiate between a large architect designed construction, and a large elevated soil/ rock construction. They will both act to converge and intensify E Field, and therefore have a higher disposition to being struck

Lightningman- Leaders in lightning risk mitigation and innovation.

Grant Kirkby – Lightningman